Screen printing is a process of transferring ink onto a fabric background. The process of screen printing is still very simple – emulsion is pressed through a mesh or printed film that acts as a stencil. This stencil can be completely customised for any design, and whilst you can print up to 8 colours when screen printing, we recommend sticking to 4 or less – depending on the design, with more than 4 colours, your artwork might work better as a full colour transfer print.

This process is perfect for t-shirts and fabric printed bags for branded logos, emblems, slogans and so much more. Screen printing has developed over hundreds of years but is most associated with 60s pop art. Today, we have newer, modern technology and precision designs for even better printing; for example, most graphic designers now use InDesign and laser printing to create their films (below) to ensure a sharp design.

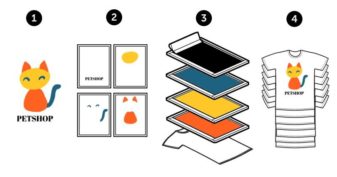

What Is The Screen Printing Process?

Image Credit: camaloon.com

- Image is printed into the ‘film’. Essentially, this is a transparent sheet of paper. Remember, different colours must be printed onto different films.

- The film will then be placed on the correct side of the frame. It is important to measure where the film is placed to ensure multiple films print exactly where they are meant to. This will also prevent any unwanted overlapping and ruined prints. #

- The screen frame is placed film-side down on a negative printer. This is repeated for all the films.

- After the negative print is complete, remove the film and then wash down the screen. It is best to wash off from the press-side, rather than the film-side of the screen, because this is the exposed side.

- Line the design up with the print on the press as accurately as possible. Place the item, such as a printed cotton bag or t-shirt, on the block for printing.

- Finally, emulsion can be spread onto the screen frame and spread as evenly as possible. A special brush or rubber printing block will be used to spread the emulsion as it helps maintain even pressure and even colour.

- This will be repeated for all films (for all the colours in the design).

- The t-shirt or item is removed from the block and checked to see if the print was lined up correctly. If it is, the printing is repeated to fulfil the order.

What Else You Need To Know About Screen Printing

Screen printing has been around for so long because it is so simple but so effective. Screen printing produces high-quality results and is so popular because it transfers bright, bold colours even onto darker colours. For branded merchandise, this means a business logo can contrast with a background fabric to make it really pop!

Screen printing will also maintain quality. Unlike many other methods of printing which do not last well and do not have a precise, quality transfer, screen printing will produce a durable item that can be washed without fear that the design will disappear.

If you are thinking about making an order for screen printing with new branding or to launch your business, you should be aware that screen printing transfers onto some fabrics better than others. A general rule of thumb is to keep things as natural as possible. This is because synthetics have more plastic and oil and do not absorb water (and thus the colour emulsion) as well. Printed cotton bags or a high quality printed canvas bags will produce the best results for screen printed designs.

Wherever possible, bear in mind the type of printing you might require when designing your logo or branding. It is important that the image file used for screen printing is a vector. Unfortunately, because of the process of screen printing, it is not possible to achieve a gradient or fade-effect with this method -this kind of design would require a transfer print, which you can read a little more about in this blog post.

Screen printing is effective for businesses and branded merchandise because it is extremely cost effective for mass order. A printing block or frame will have to be created for any unique design, but it can then be re-used for the full order. It is also a really quick process once it gets going.

For more information or to make an order today, get in touch with the team at The Printed Bag Shop, today!